The Ansul R-102 Manual serves as the primary resource for understanding and operating the R-102 fire suppression system, essential for commercial kitchen safety and compliance.

1.1 Overview of the Ansul R-102 Fire Suppression System

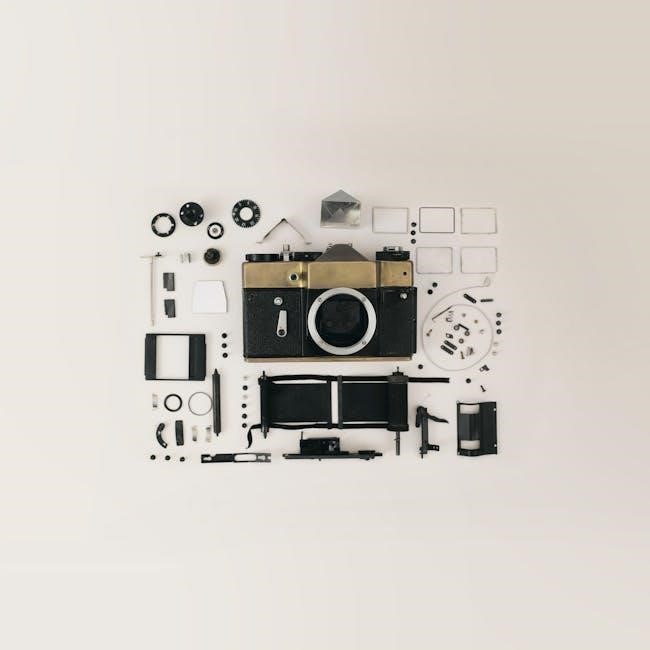

The Ansul R-102 is a clean agent fire suppression system designed primarily for commercial kitchen applications. It effectively addresses Class B and Class C fires, offering rapid response and reliable protection. The system is self-contained, featuring components such as a tank, nitrogen cartridge, saponifier, piping, fusible links, drops, and nozzles. UL 300 certified, it ensures compliance with safety standards and integrates seamlessly with kitchen ventilation systems, making it a preferred choice for fire safety in restaurants and food service environments.

1;2 Importance of the Manual for Users

The Ansul R-102 Manual is crucial for users, providing detailed instructions for installation, operation, and maintenance. It ensures proper system function, compliance with safety standards, and adherence to UL 300 certification. The manual guides users through troubleshooting, recharge procedures, and regular inspections, enhancing safety and efficiency. By following the manual, users can maintain system reliability and effectiveness, ensuring optimal fire protection in commercial kitchens and food service environments. It serves as an essential reference for installers, operators, and maintainers.

Key Features and Components of the Ansul R-102 System

The R-102 system features a clean agent, nitrogen cartridge, saponifier, piping, fusible links, drops, and nozzles, designed for effective fire suppression in commercial kitchens.

2.1 Description of the Clean Agent Technology

The Ansul R-102 employs clean agent technology, utilizing a fire-suppressing foam that leaves no residue, making it ideal for commercial kitchens. This innovative system discharges a soapy solution, created by mixing water with a saponifier, effectively smothering fires without damaging equipment. The clean agent technology ensures quick fire suppression while maintaining a safe and clean environment, crucial for food preparation areas.

2.2 Main Components: Tank, Nitrogen Cartridge, Saponifier, and Piping

The Ansul R-102 system consists of a storage tank holding the fire-suppressing agent, a nitrogen cartridge acting as the propellant, a saponifier mixing with water to create a soapy solution, and a network of piping distributing the agent. These components work together seamlessly to ensure effective fire suppression in commercial kitchens, providing a reliable and efficient solution for fire safety.

2.3 Fusible Links, Drops, and Nozzles

The Ansul R-102 system relies on fusible links to detect heat and trigger the release of the suppression agent. These links are designed to activate at specific temperatures, ensuring a timely response. The system also includes drops and nozzles, which are strategically placed to distribute the agent efficiently across protected areas. Together, these components ensure that the R-102 system provides effective and reliable fire suppression in commercial kitchen settings, enhancing overall safety.

Design and Application of the Ansul R-102 System

The R-102 system is specifically engineered for commercial kitchen environments, offering advanced fire protection for cooking appliances, hoods, and ducts, ensuring reliable suppression of Class B and Class C fires.

3.1 Primary Use in Restaurant and Commercial Kitchens

The Ansul R-102 system is specifically designed for restaurant and commercial kitchen environments, providing reliable fire protection for cooking appliances, hoods, and ducts. It is highly effective in suppressing Class B and Class C fires, commonly occurring in these settings. The system’s clean agent technology ensures minimal damage to equipment and is UL 300 compliant, making it a trusted solution for commercial kitchens. Its tailored design allows for seamless integration into various kitchen layouts, ensuring maximum fire protection without disrupting operations.

3.2 Compatibility with Class B and Class C Fires

The Ansul R-102 system is specifically designed to combat Class B and Class C fires, which involve flammable liquids and electrical equipment, respectively. Its clean agent technology effectively extinguishes these fires without leaving residue, making it ideal for protecting sensitive kitchen equipment. The system’s rapid response ensures minimal damage, and its compliance with UL 300 standards guarantees reliability in high-risk environments like commercial kitchens.

Installation Requirements and Guidelines

Proper installation of the Ansul R-102 system ensures safety and efficiency, requiring adherence to manufacturer guidelines and compliance with fire protection standards to minimize risks and optimize performance.

4.1 Steps for Proper System Installation

Proper installation begins with site preparation, ensuring all components are compatible and correctly positioned. Next, install the tank, nitrogen cartridge, and saponifier according to the P&ID. Connect piping meticulously, ensuring no leaks. Install fusible links, drops, and nozzles in strategic locations. Finally, test the system to ensure all components function correctly and comply with UL 300 standards. Follow the manual closely for precise guidance and safety.

4.2 Piping and Instrumentation Diagram (P&ID)

The P&ID provides a detailed visual representation of the Ansul R-102 system’s components and connections. It outlines the layout of the tank, nitrogen cartridge, saponifier, piping, and nozzles. This diagram is essential for installers to ensure proper system configuration and compliance with UL 300 standards. The P&ID also highlights flow directions and connections, aiding in troubleshooting and maintenance. Referencing the P&ID ensures accurate installation and optimal system performance, particularly for designs like the 2 x 3 gallon setup for upper crest tower applications.

Operation and Maintenance

Regular inspection and maintenance are crucial for the Ansul R-102 system’s reliability. Ensure all components function correctly and address any issues promptly to maintain fire protection integrity.

5.1 Regular Inspection and Maintenance Tasks

Regular inspections are essential to ensure the Ansul R-102 system operates effectively. Check the nitrogen cartridge pressure, inspect fusible links, nozzles, and piping for damage or blockages. Verify the saponifier is securely connected and functioning properly. Ensure all electrical connections are intact and test the system’s manual pull station. Refer to the manual for detailed procedures and maintain a record of inspections. Proper maintenance ensures reliability and compliance with safety standards like UL 300.

5;2 Recharge and Refill Procedures

Recharging and refilling the Ansul R-102 system must be performed by certified technicians to ensure safety and effectiveness. After discharge, inspect the system for damage or leaks. Replace the nitrogen cartridge and refill the clean agent to the recommended levels using Ansul-approved agents. Follow the manual’s step-by-step guide for proper recharging to maintain system integrity. Always adhere to UL 300 standards and record the procedure for future reference. Proper recharging ensures the system remains ready for emergency situations.

Troubleshooting and Advanced User Guide

This section provides solutions for common issues and advanced diagnostic techniques to ensure optimal system performance and reliability in critical fire suppression scenarios.

6.1 Common Issues and Solutions

Common issues with the Ansul R-102 include regulator failure, nitrogen cartridge leaks, or saponifier malfunctions. Solutions involve replacing faulty components and ensuring proper system recharge. Diagnostic checks for false discharges or low pressure are essential. Always refer to the P&ID for accurate troubleshooting. Regular maintenance and inspections can prevent these issues. Addressing problems promptly ensures reliable fire suppression performance.

6.2 Diagnostic Techniques for System Performance

To ensure optimal performance, conduct regular diagnostic checks on the Ansul R-102 system. Inspect the regulator, nitrogen cartridge, and saponifier for proper function. Pressure-test the piping and nozzles to identify blockages or leaks. Review the P&ID for accurate system layout and flow. Perform routine maintenance checks and log results for compliance. These steps help maintain reliability and ensure the system is ready for emergencies.

Compliance and Safety Standards

The Ansul R-102 system complies with UL 300 certification, ensuring reliability for Class B and Class C fires. Adherence to safety standards guarantees effective and secure operation.

7.1 UL 300 Certification and Other Relevant Standards

The Ansul R-102 system is UL 300 certified, meeting rigorous standards for fire suppression in commercial kitchens. This certification ensures the system’s effectiveness against Class B and Class C fires, providing reliable protection for cooking appliances and ventilation systems. Compliance with UL 300 demonstrates adherence to industry benchmarks for safety and performance, making the R-102 a trusted solution for fire suppression needs.

7.2 Safety Precautions for Handling and Operation

Always follow safety guidelines when handling the Ansul R-102 system. Wear protective gear, ensure proper ventilation, and avoid exposure to released agents. Regularly inspect components for damage or leaks. Maintain a safe distance during system activation and ensure personnel are trained in emergency procedures. Adhere to all safety standards and manufacturer recommendations to ensure system reliability and user safety. Proper handling and operation are critical to preventing accidents and ensuring effective fire suppression.

Ansul R-102 Restaurant Fire Suppression System

The Ansul R-102 system is specifically designed for restaurant fire protection, offering tailored solutions to safeguard cooking appliances, hoods, and ventilation systems effectively.

8.1 Tailored Solutions for Kitchen Fire Protection

The Ansul R-102 system offers customized fire protection solutions designed specifically for commercial kitchens. It ensures rapid suppression of Class B and Class C fires, protecting cooking appliances, ducts, and hoods. The system’s clean agent technology minimizes downtime and damage, making it ideal for busy restaurant environments. Its flexible design allows for seamless integration with existing kitchen layouts and ventilation systems, providing comprehensive fire safety without compromising operations.

8.2 Integration with Ventilation Systems

The Ansul R-102 system seamlessly integrates with commercial kitchen ventilation systems, ensuring efficient fire suppression without disrupting airflow. Its design allows for synchronization with exhaust hoods and ducts, providing comprehensive protection. This integration enhances safety by preventing fire spread through ventilation pathways, a critical feature in high-risk kitchen environments. The system’s compatibility with standard ventilation setups ensures easy installation and maintenance, making it a reliable choice for modern commercial kitchens.

Handling and Storage of System Components

Proper handling and storage of Ansul R-102 components ensure system reliability. Store in dry, cool environments, avoiding direct sunlight and moisture. Follow manufacturer guidelines for transportation and delivery.

9.1 Proper Storage Conditions for Components

Store Ansul R-102 components in a cool, dry, well-ventilated area, away from direct sunlight and moisture. Maintain a temperature range of 32°F to 100°F (0°C to 38°C). Ensure components are protected from physical damage and contamination. Keep cylinders upright and secure to prevent tipping. Avoid exposure to extreme humidity or corrosive environments. Follow all manufacturer guidelines for handling and storage to preserve system integrity and performance. Proper storage ensures safety and reliability of the fire suppression system.

9.2 Transportation and Delivery Guidelines

Ensure all Ansul R-102 components are securely packaged and transported in an upright position to prevent damage. Avoid exposure to extreme temperatures, vibration, or physical stress during transit. Use approved carriers and adhere to local transportation regulations. Inspect components upon delivery for visible damage or tampering. Document any issues and report them immediately. Proper handling during transportation ensures components arrive in optimal condition for installation and operation, maintaining system reliability and safety standards.

The Ansul R-102 Manual provides comprehensive guidance for safe and effective fire suppression in commercial kitchens, ensuring compliance and optimal system performance for user confidence and reliability.

10.1 Summary of Key Points

The Ansul R-102 Manual outlines essential steps for installation, operation, and maintenance of the fire suppression system, emphasizing safety, compliance, and system longevity. It covers critical components like the clean agent technology, fusible links, and piping, ensuring users understand proper usage and troubleshooting. Regular inspections and adherence to UL 300 standards are highlighted to maintain effectiveness and reliability, providing a comprehensive guide for commercial kitchen fire protection.

10.2 Final Recommendations for Users

Users should always follow the Ansul R-102 Manual guidelines for installation, operation, and maintenance to ensure optimal performance and safety. Regular inspections and adherence to UL 300 standards are crucial. Proper handling and storage of components, along with timely recharges, are recommended. Stay updated with the latest manual revisions and manufacturer guidelines. Tailor the system to specific kitchen needs and integrate with ventilation systems for enhanced protection. Ensure emergency procedures are in place and consult certified professionals for advanced tasks.