Saint Hildegard of Bingen, a renowned medieval mystic and polymath, authored groundbreaking medical texts. Her manual combines natural healing, spirituality, and holistic wellness, offering remedies for various ailments.

1.1 Historical Background of Saint Hildegard of Bingen

Saint Hildegard of Bingen (1098–1179) was a German Benedictine abbess, mystic, and polymath. Recognized as a Doctor of the Church in 2012, she was a pioneer in theology, music, and medicine; Born into a noble family, Hildegard experienced visions from an early age, which she later documented. Her medical writings, including Physica and Causae et Curae, reflect her holistic understanding of health, blending natural remedies with spiritual insights; Her work remained influential for centuries, establishing her as a foundational figure in medieval medicine and spirituality.

1.2 The Significance of Her Medical Works

Saint Hildegard’s medical works are remarkable for their holistic approach, integrating natural remedies, spirituality, and dietary advice. Her texts, Physica and Causae et Curae, detail treatments for various ailments, emphasizing the balance of the four humors. These works not only preserve medieval medical knowledge but also showcase her innovative understanding of human health. Her remedies, often based on herbs and natural elements, remain relevant today, attracting modern interest in alternative medicine. Hildegard’s contributions to medicine highlight her enduring influence as a scholar, healer, and visionary.

1.3 Overview of the Free PDF Manual

The free PDF manual, based on Saint Hildegard’s visions, offers a comprehensive guide to natural healing. Published by Libros Libres, it includes her renowned works, Physica and Causae et Curae, detailing herbal remedies, dietary advice, and holistic treatments. The manual is accessible for download, providing insights into medieval medicine while remaining relevant today. It serves as a valuable resource for those exploring alternative health, blending spirituality and science. This PDF is a testament to Hildegard’s enduring legacy, making her wisdom available to a global audience.

Key Concepts in Saint Hildegard’s Medicine

Saint Hildegard’s medicine emphasizes natural healing, spirituality, and the balance of the four humors. Her approach integrates physical and spiritual health, offering holistic remedies for wellness and disease prevention.

2.1 The Philosophy of Natural Healing

Saint Hildegard’s medicine revolves around the philosophy of natural healing, emphasizing the use of herbs, water, and minerals to restore balance. She believed the human body was a microcosm of the universe, requiring harmony between physical and spiritual elements. Her approach focused on preventing illness by aligning with nature’s rhythms and promoting self-healing through holistic remedies. This philosophy underpins her belief in the interconnectedness of body and soul, advocating for treatments that address both physical ailments and spiritual imbalances. Her manual provides practical guidance on harnessing nature’s healing properties for overall wellness.

2.2 The Role of Spirituality in Medicine

Saint Hildegard’s medical philosophy deeply integrates spirituality, viewing the body and soul as interconnected. She believed that true healing required addressing both physical ailments and spiritual imbalances. Her works emphasize that health is a divine gift, and illness often reflects a disconnection from God’s natural order. Hildegard advocated for prayer, faith, and moral living as essential components of recovery. She saw the human body as a microcosm of the universe, created in God’s image, and her remedies often included spiritual practices to restore harmony and balance. This holistic approach remains central to her teachings, blending medicine with divine wisdom.

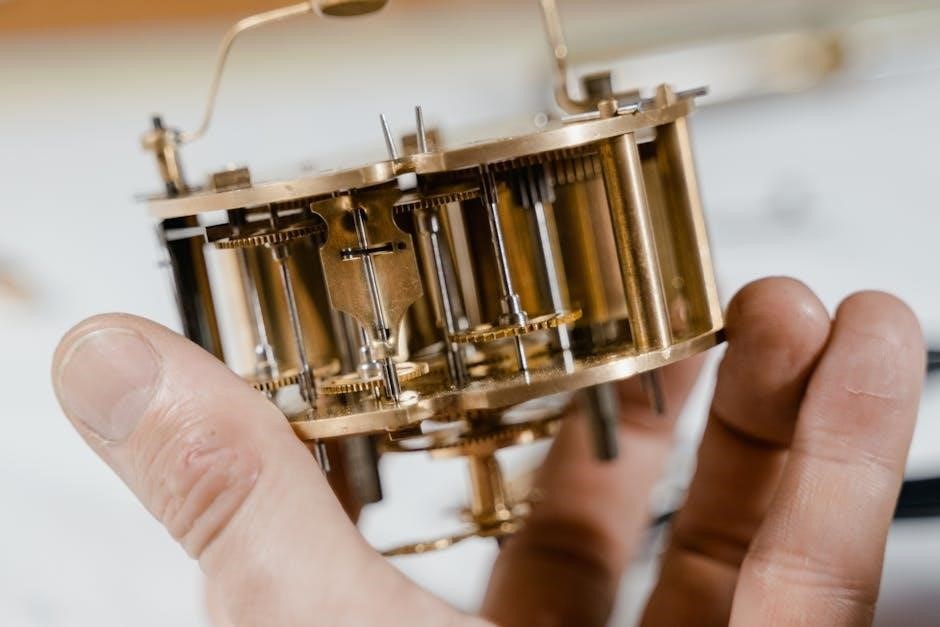

2.3 The Four Humors and Their Balance

Saint Hildegard’s medical teachings emphasize the balance of the four humors—blood, phlegm, yellow bile, and black bile—as crucial for health; Drawing from ancient medical theory, she believed these humors must be in harmony to maintain well-being. Imbalances were thought to cause illness, and her remedies often aimed to restore equilibrium. Hildegard linked this concept to the interconnectedness of body and soul, advocating for holistic healing. Her approach to medicine thus combined natural remedies with spiritual principles, ensuring treatments addressed both physical and metaphysical aspects of health. This balance remains a cornerstone of her enduring medical philosophy.

Major Medical Works by Saint Hildegard

Saint Hildegard authored Physica and Causae et Curae, foundational texts in medieval medicine. These works explore natural remedies, spiritual healing, and holistic health principles, influencing modern practices.

3.1 Physica (Book of Simple Medicine)

Physica, or the Book of Simple Medicine, is a comprehensive guide by Saint Hildegard detailing natural remedies and the medicinal properties of plants, animals, and minerals. It emphasizes holistic healing, connecting physical health with spiritual well-being. The text provides practical treatments for common ailments, showcasing Hildegard’s deep understanding of nature’s healing powers. This work remains a cornerstone of her medical contributions, offering accessible wisdom for health and wellness. Its principles continue to inspire modern alternative medicine practices, highlighting the timeless relevance of her teachings.

3.2 Causae et Curae (Book of Complex Medicine)

Causae et Curae, or the Book of Complex Medicine, delves into the intricate relationships between human physiology, spirituality, and the natural world. This work explores the causes of diseases and offers detailed treatments, blending theology with medical science. Unlike Physica, it focuses on more severe and chronic conditions, providing advanced remedies and therapeutic approaches. Hildegard’s deep understanding of the interplay between body and soul is evident, making this text a valuable resource for those seeking a deeper understanding of her holistic medical philosophy and its practical applications in healing.

Remedies and Treatments in the Manual

The manual offers herbal remedies, dietary advice, and natural cures for common ailments, emphasizing a holistic approach to health and wellness, blending nature and spirituality.

4.1 Herbal Remedies and Their Applications

Saint Hildegard’s manual emphasizes herbal remedies, leveraging nature’s healing properties. Herbs like fennel, marjoram, and chamomile are recommended for digestive issues, respiratory problems, and stress relief. The manual details how to prepare these remedies, such as teas, salves, and tinctures, ensuring safe and effective use. Hildegard’s approach focuses on balancing the body’s humors and restoring vitality. She also highlights the spiritual dimension of healing, encouraging the use of prayers and meditation alongside herbal treatments. These natural solutions remain popular today, offering holistic alternatives for modern health concerns.

4.2 Dietary Recommendations for Health

Saint Hildegard’s manual advocates for a balanced diet to maintain health and prevent illness. She emphasizes moderation, avoiding excess, and consuming natural, wholesome foods. Hildegard recommends whole grains, fruits, vegetables, and lean meats, while cautioning against overindulgence in rich or fatty foods. She also advises on the spiritual aspect of eating, suggesting grace before meals to foster gratitude and mindfulness. Her dietary teachings align with modern principles of nutrition, promoting a holistic approach to wellness that unites body, mind, and spirit. These guidelines remain a cornerstone of Hildegardian medicine, offering timeless wisdom for healthy living.

4.3 Natural Cures for Common Ailments

Hildegard’s manual offers natural remedies for common ailments, emphasizing herbal and plant-based treatments. For colds, coughs, and flu, she recommends fennel, marjoram, and mustard to alleviate symptoms. Hildegard also suggests using natural elements like warm compresses and steam inhalation to soothe respiratory issues. Her remedies often combine practical applications with spiritual practices, promoting overall well-being. These natural cures reflect her belief in the interconnectedness of physical and spiritual health, providing effective, holistic solutions that resonate with modern natural medicine approaches. Her methods remain a testament to the enduring wisdom of her medical insights.

Modern Relevance of Hildegardian Medicine

Hildegard’s holistic medical philosophy resonates with modern integrative healthcare, emphasizing natural remedies and spiritual balance. Her herbal treatments and dietary advice align with contemporary wellness trends, offering sustainable health solutions.

5.1 Integration with Contemporary Healthcare

Hildegardian medicine seamlessly integrates with modern healthcare by complementing conventional treatments with natural remedies. Her holistic approach, emphasizing herbal therapies and dietary balance, aligns with today’s focus on integrative medicine. The use of natural substances like fennel, chamomile, and galangal, as highlighted in her works, resonates with contemporary wellness trends. Additionally, her philosophy of balancing the mind, body, and spirit supports current mind-body therapies. This synergy makes Hildegard’s teachings a valuable resource for modern healthcare, offering sustainable and holistic health solutions that enhance traditional practices and promote overall well-being.

5.2 Popularity of Hildegardian Remedies Today

Hildegardian remedies are experiencing a resurgence in popularity today, driven by a growing interest in natural and holistic health solutions. The availability of free PDF manuals like Manual de Medicina de Santa Hildegarda has made her teachings accessible to a global audience. Her emphasis on herbal medicine, such as fennel and chamomile, aligns with contemporary wellness trends. Additionally, her holistic approach, combining physical and spiritual healing, resonates with modern integrative health practices. This timeless wisdom attracts those seeking sustainable and natural alternatives, making Hildegard’s remedies a cherished resource in today’s health-conscious world.

How to Access the Free PDF Manual

Access the free PDF manual through trusted sources like Libros Libres or Amazon. Ensure authenticity by downloading from verified platforms for safe and reliable access always.

6.1 Trusted Sources for Download

Download the free PDF manual from trusted sources like Libros Libres or Amazon. These platforms offer verified versions, ensuring authenticity and safety. Always verify the publisher and author, such as Dr. Wighard Strehlow, to avoid counterfeit copies. Additionally, check for watermarks or official seals that confirm the manual’s legitimacy. Avoid unverified websites to prevent downloading fraudulent or incomplete versions. Prioritize sources with positive reviews or those affiliated with reputable publishers to ensure a genuine and high-quality download experience for Manual de Medicina de Santa Hildegarda.

6.2 Tips for Effective Use of the Manual

For effective use, start by consulting a healthcare professional before applying remedies. Cross-reference the manual with Saint Hildegard’s original works, such as Physica and Causae et Curae, for deeper understanding. Focus on herbal remedies and dietary advice, ensuring proper preparation methods. Keep a balanced approach, integrating spiritual and natural healing practices. Regularly update your knowledge with modern medical advancements while respecting the manual’s historical context. Use the guide as a complementary tool for wellness, fostering a holistic approach to health and spirituality as envisioned by Saint Hildegard.